Jakość systemów kolejowych ALMiG

Nasza firma jest w stanie stale poprawiać niezawodność produktów, dzięki nowoczesnym technologiom produkcyjnym, wysoce rozwiniętej inżynierii testowej oraz kompleksowemu systemowi zarządzania jakością.

Jako oficjalny, w naszym kraju, przedstawiciel AMLiG Kompressoren BmbH gwarantujemy, że producent systemów wytwarzania i uzdatniania powietrza (AGTU) wytwarza komponenty, które działają niezawodnie. Każdy element sprzętu jest stworzony z troską o najdrobniejszy szczegół, aby możliwe było 100% zagwarantowanie bezpieczeństwa pojazdu. Właśnie dlatego firma ALMiG na pierwszym miejscu swojej filozofii stawia jakość.

Producent z certyfikatem IRIS

Standardy określane w certyfikacie IRIS są uznawane przez wszystkich głównych producentów szyn kolejowych. Dla dostawców technologii kolejowych standard IRIS ma równie duże znaczenie – najwięksi producenci systemów stawiają go jako warunek wstępny i konieczny dla dostawców klasy A. Firma ALMiG Rail Systems od lat posiada certyfikat IRIS. Dzięki temu czołowy producent kompresorów powietrza i sprężarek spełnia wszystkie, nawet najbardziej surowe wymagania jakościowe branży kolejowej, które wykraczają poza zwykłe standardy.

Kolejowe produkty ALMiG z certyfikatami ISO

ALMiG, producent systemów kolejowych może się pochwalić aż trzema certyfikatami ISO:

- certyfikat ISO 9001 – zawiera wymagania dotyczące systemu, które mają zastosowanie, gdy organizacja potrzebuje wykazać zdolność do ciągłego dostarczania wyrobu spełniającego wymagania rynkowe,

- certyfikat ISO 14001 – funkcjonuje na podstawie międzynarodowych standardów i jest potwierdzeniem wdrażania wszystkich elementów, które przyczyniają się do ograniczenia negatywnego wpływu firmy na środowisko,

- certyfikat ISO 15085 – oznacza spełnienie międzynarodowych norm branży kolejowej w zakresie spawania oraz wysokiej jakości spawania materiałów w produkcji komponentów i taborze.

Nasz system zarządzania dokłada wszelkich starań, aby dostosować się do systemu ALMiG, gdzie zarządzanie jakością obejmuje wszystkie niezbędne systemy biznesowe – zaczynając od rozmowy z klientem, kończąc na gotowym produkcie. Równie ważnymi elementami niezawodnego systemu jakości są regularne szkolenia i ciągłe doskonalenie każdego z pracowników.

Wszyscy wykwalifikowani specjaliści i inżynierowie zajmujący się spawaniem, zapewniają wysoką jakość wykonania każdego projektu i każdej pojedynczej części.

Specjalne kontrole i testy produktów ALMiG

Standardy jakości i niezawodności produktów ALMiG znacząco przewyższają podstawowe wymagania w sektorze przemysłowym. Dowodem na to są liczne kontrole i testy przeprowadzone przez producenta systemów kolejowych. Poniżej przedstawiamy kluczowe analizy przeprowadzane w celu utrzymania w produktach kolejowych wysokich standardów jakości.

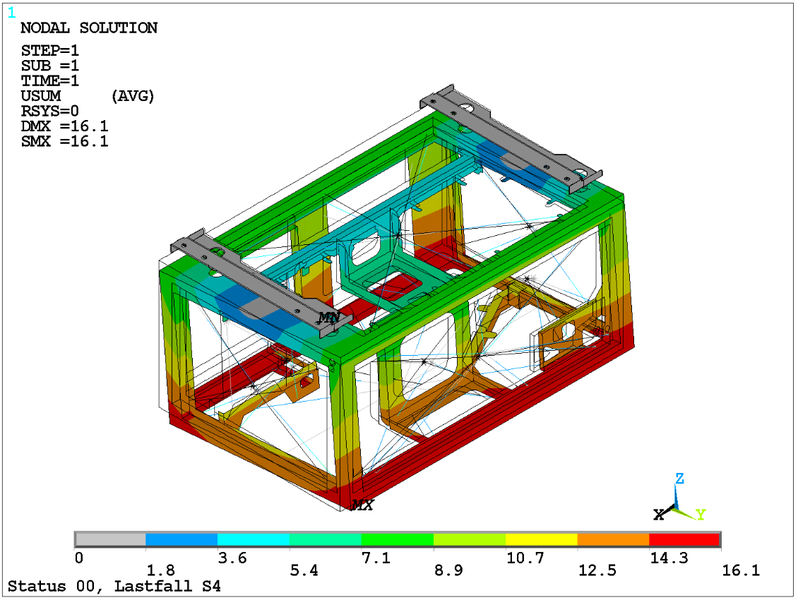

Analiza FEM

W przeprowadzanych testach warunki obciążenia są stymulowane dla wszystkich konstrukcji sprężarek szynowych, a przy tym obliczany jest szczegółowy model FEM. Warunki obciążenia statycznego są zgodne z normą DIN 12663 dla pojazdów pasażerskich kategorii III (metra i pociągi podmiejskie).

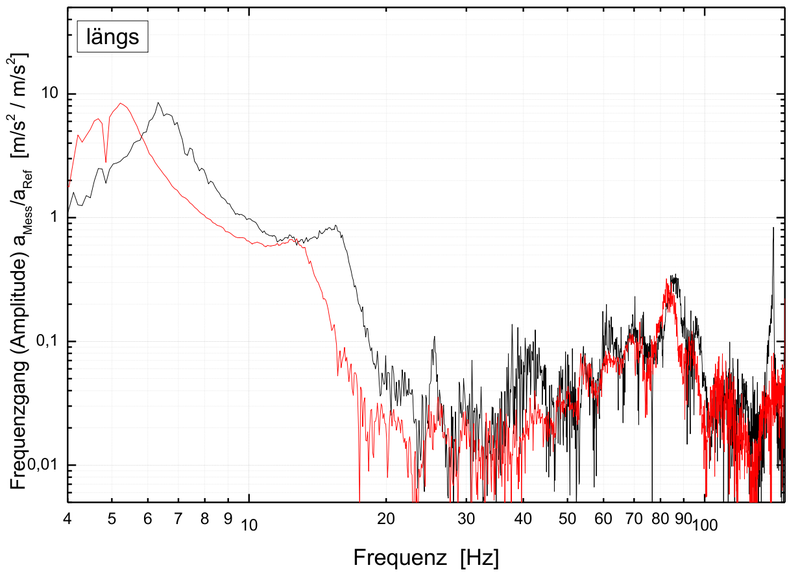

Testy wstrząsów i wibracji

W czasie tych testów stymulowany jest cykl życia systemu wytwarzania powietrza. Kontrole przeprowadzane są w specjalnie zaprojektowanych centrach testowych, a cały proces odbywa się w ekstremalnych warunkach. Cały test polega na symulowaniu użytkowania sprężarki przez okres przekraczający 30 lat. Systemy są sprawdzane zgodnie z normą DIN EN 61373.

Komora klimatyczna

Przydatność naszych sprężarek po raz kolejny testowana jest w niezwykle ekstremalnych warunkach, tym razem klimatycznych. Specjalne zaprojektowane komory klimatyczne wykorzystywane są w celu sprawdzenia zachowania systemów w temperaturach -50*C do +70*C. Producent szczególną wagę przywiązuje do zminimalizowania wpływu temperatury na cały system i zapewnienia jego bezpieczne funkcjonowanie podczas pracy pociągu.

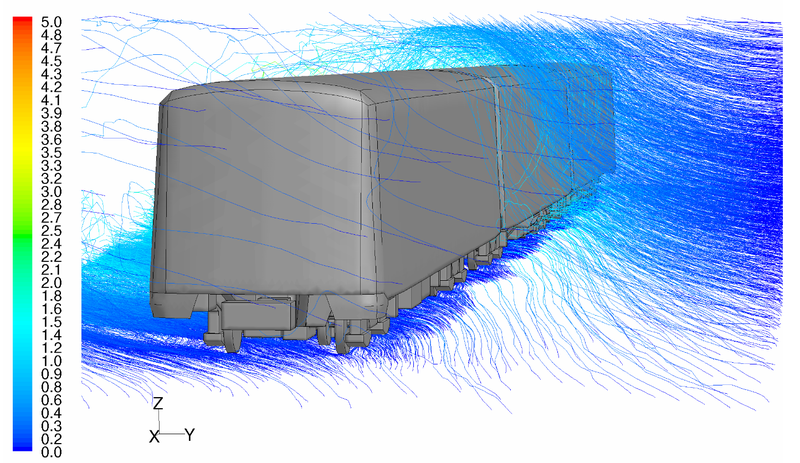

Stymulacja śniegu i lodu

W celu sprawdzenia zachowania systemów na zimowe warunki, produkty ALMiG są poddawane symulacji śniegu. Obejmuje ona ocenę systemów kolejowych w różnych środowiskach operacyjnych poprzez symulację cząstek śniegu i lodu. Testy sprawdzają między innymi takie sytuacje jak jazda z normalną prędkością na otwartym torze z opadami śniegu i wiatrem z przodu.

Testy korozyjne we mgle solnej

Systemy ALMiG są poddawanie testom przeciwkorozyjnym w celu sprawdzenia wysokiej jakości powłok w produktach. Sprężarki są intensywnie testowane przez okres od 6 do nawet 1000 godzin (w zależności od specyfikacji klienta). Pozwala to na zweryfikowanie żywotności komponentów nawet w trudnych warunkach atmosferycznych, które sprzyjają powstawaniu korozji (np. kwaśne deszcze).

RAMS/LCC

W inżynierii RAMS służy do scharakteryzowania produktu lub systemu. Poszczególne litery w tłumaczeniu z języka angielskiego oznaczają:

- niezawodność – dotyczy niezawodności projektowej, jak i niezawodności operacyjnej decydującej o zdolności do wykonywania określonej funkcji,

- dostępność – inaczej zdolność do utrzymania stanu funkcjonowania w danym środowisku,

- łatwość konserwacji – w tym zdolność do prostego i bezproblemowego serwisowania, inspekcji i kontroli oraz naprawy i/lub modyfikacji,

- bezpieczeństwo – produkty powinny zapewniać nieszkodliwe skutki używania produktów zarówno dla ludzi, jak i zwierząt i całego środowiska podczas całego cyklu funkcjonowania.

Wszystkie produkty ALMiG są opracowane wraz z ogromnym naciskiem na niezawodność, łatwość konserwacji, bezpieczeństwo oraz dostępność. Codziennie staramy się udowadniać wszystkie zalety systemów klientom na całym świecie. Każdy z klientów, wraz z dokonaniem zakupu, otrzymuje szczegółowe informacje dotyczące tego, jak spełniać wszystkie wymagania RAMS.

Life Cycle Cost (LCC) z kolei ma na celu ocenę wielkości kosztów ponoszonych za stworzenie i użytkowanie obiektu. LCC dostarcza również ważne dane wyjściowe do procesu podejmowania decyzji podczas projektowania, rozwoju, wytwarzania, eksploatacji i likwidacji obiektu. Producent kolejowych systemów szczególną zwraca szczególną uwagę i dokłada wszelkich starań, aby produkty zapewniały minimalne koszty cyklu życia, zaczynając już od fazy przetargu.

Systemy kolejowe