U wielu operatorów można zaobserwować problemy z układami pneumatycznymi lub hamulcowymi. Często wynikają one z niskiej jakości urządzeń lub wadliwych sprężarek. W takich przypadkach w prosty sposób można wymienić urządzenie na jedną z niezawodnych sprężarek ALMiG.

Bardzo często zdarzają się również sytuacje, gdy problemy z prawidłowym funkcjonowaniem sprężarki są spowodowane niskiej jakości, zanieczyszczonym sprężonym powietrzem. Wszystko, co jest zasysane przez sprężarkę, zwykle opuszcza wylot sprężonego powietrza w postaci sprężonego gazu, cząstek stałych, kurzu, brudu i wilgoci. Substancje są możliwe do przefiltrowania przez system uzdatniania TAD firmy ALMiG, dzięki czemu niezawodność systemu zostaje znacznie zwiększona.

Systemy uzdatniania powietrza TAD dla sektora kolejowego

Firma ALMiG, którego jesteśmy oficjalnym przedstawicielem na terenie Polski, oferuje szeroką gamę systemów uzdatniania sprężonego powietrza dla sektora kolejowego. Systemy te mogą zostać zintegrowane z systemem wytwarzania powietrza w fabryce, jak również mogą później być modernizowane. Systemy uzdatniania powietrza TAD są także kompatybilne ze wszystkimi sprężarkami dostępnymi na rynku.

ALMiG, jako przodujący dostawca wszystkich komponentów do wytwarzania i uzdatniania powietrza, nieustannie inwestuje w badania i rozwój technologiczny sprężarek powietrza. Ogromne zaangażowanie przyczyniło się do stworzenia wysokiej jakości, innowacyjnych systemów uzdatniania powietrza w przemyśle kolejowym, które przedstawiamy poniżej.

Osuszacze adsorpcyjne

Osuszacze adsorpcyjne (systemy jednokomorowe i dwukomorowe) służą do osuszania powietrza z zawartej w nich pary wodnej z wykorzystaniem właściwości materiału higroskopijnego. Działanie osuszacza polega na przepuszczaniu powietrza przez zbiornik z tzw. absorbentem, który wytrąca wilgoć. Substancja następnie jest poddawana regeneracji, czyli osuszeniu powietrza przez oddzielny zbiornik odbierający wilgoć i odprowadzający ją za zewnątrz. W procesie regeneracji tracone jest około 15% dostarczanego powietrza. Istotną rolę odgrywa tutaj układ sterujący – rozdziela powietrze między dwoma zbiornikami oraz zapewnia stały poziom wyjściowych parametrów powietrza.

Separatory wody sprężonego powietrza

Separacja wody oraz oleju w układach sprężonego powietrza jest skomplikowanym procesem, który zapewnia zgodności z przepisami i zminimalizowanie zanieczyszczenia środowiska. Separatory wody sprężonego powietrza (separatory cyklonowe) zostają zainstalowane przed chłodnicami sprężonego powietrza, za sprężarkami powietrza i przed osuszaczami sprężonego powietrza. Są przeznaczone do usuwania sprężonego powietrza z instalacji oraz usuwania innych mediów gazowych wody i zanieczyszczonych płynów w postaci kondensatu.

Filtry sprężonego powietrza

Filtracja jest jednym z podstawowych procesów uzdatniania sprężonego powietrza i jest obecna na kilku etapach w cyklu obróbki powietrza. Uniwersalne filtry usuwają wszystkie rodzaje stałych i płynnych zanieczyszczeń. W pierwszym etapie, czyli wstępnej filtracji, usuwane są spore ilości kondensatu olejowego, a także wody i cząstek stałych w takich postaciach jak rdza, pył, czy krople oleju. W kolejnych etapach filtracja opiera się na czyszczeniu drobnych cząstek stałych i mgły olejowej.

W ofercie ALMiG z wyjątkiem klasycznych filtrów sprężonego powietrza dostępne są również dwa inne rodzaje produktu:

- filtry sprężonego powietrza o zwiększonej wydajności,

- filtry przeciwpyłowe sprężonego powietrza (filtr końcowy za osuszaczem).

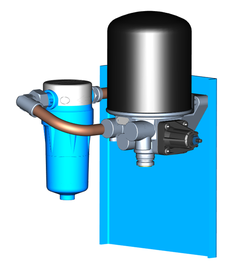

TAD 400 – osuszacz jednokomorowy

- Maksymalna wydajność suszenia – 400 l/min;

- Redukcja punktu rosy – -25K;

- Maksymalne ciśnienie robocze – 10 bar (nadciśnienie);

- Wymiary (dł. x szer. x wys.) – 145 mm x 175 mm x 348 mm;

- Waga – 11 kg.

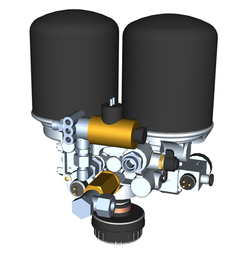

TAD 1000 – osuszacz dwukomorowy

- Maksymalna wydajność suszenia – 1000 l/min;

- Redukcja punktu rosy – -25K;

- Maksymalne ciśnienie robocze – 10 bar (nadciśnienie);

- Wymiary (dł. x szer. x wys.) – 296 mm x 175 mm x 348 mm;

- Waga – 22 kg.

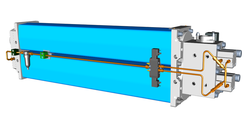

TAD 2000 – równoległa suszarka dwukomorowa

- Maksymalna wydajność suszenia – 2000 l/min;

- Redukcja punktu rosy – -25K;

- Maksymalne ciśnienie robocze – 10 bar (nadciśnienie);

- Wymiary (dł. x szer. x wys.) – 700 mm x 175 mm x 348 mm;

- Waga – 44 kg.

TAD 2500 – pozioma suszarka dwukomorowa

- Maksymalna wydajność suszenia – do 2500 l/min;

- Redukcja punktu rosy – -40K;

- Maksymalne ciśnienie robocze – 10 bar (nadciśnienie);

- Wymiary (dł. x szer. x wys.) – 1324 mm x 335 mm x 330 mm;

- Waga – 77 kg.

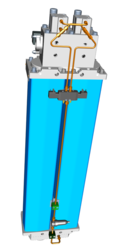

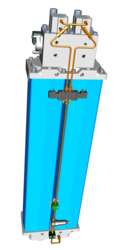

TAD 2500 – pionowa suszarka dwukomorowa

- Maksymalna wydajność suszenia – do 2500 l/min;

- Redukcja punktu rosy – -40K;

- Maksymalne ciśnienie robocze – 10 bar (nadciśnienie);

- Wymiary (dł. x szer. x wys.) – 335 mm x 330 mm x 1324 mm;

- Waga – 77 kg.

TAD 4000 – pionowa suszarka dwukomorowa

- Maksymalna wydajność suszenia – do 4000 l/min;

- Redukcja punktu rosy – -40K;

- Maksymalne ciśnienie robocze – 10 bar (nadciśnienie);

- Wymiary (dł. x szer. x wys.) – 335 mm x 330 mm x 1324 mm;

- Waga – 175 kg.

Właściwości systemów ALMiG TED dla przemysłu kolejowego

Nasze systemy uzdatniania sprężonego powietrza są w pełni zabezpieczone przed korozją dzięki obróbce alocromem i powłoce epoksydowej. Systemy można elastycznie montować zarówno pionowo, jak i poziomo, wewnątrz lub na zewnątrz pojazdu. Podobnie jak nasze sprężarki, systemy TED są testowane przez niezależne centrum pod kątem wstrząsów, wibracji, kompatybilności elektromagnetycznej i palności. Są niezwykle ciche i wolne od wibracji podczas pracy i mogą być dostosowane elektrycznie do wszystkich specyfikacji klienta.

Zalety systemu uzdatniania powietrza ALMiG TED dla przemysłu kolejowego

ALMiG zawsze gwarantuje najwyższą jakość sprężonego powietrza w swoich produktach zgodnie z międzynarodowymi standardami. Producent oferuje optymalną wydajność i ochronę systemu w każdym klimacie. Dzięki kompaktowej i lekkiej konstrukcji systemy uzdatniania powietrza, zastosowane w przemyśle kolejowym, oszczędzają miejsce i wagę, a także mają modułową konstrukcję. Gwarantują również niskie nakłady na konserwację, a niskie koszty eksploatacji mają pozytywny wpływ na koszty cyklu życia pojazdu.

Systemy kolejowe